CAESAR II

OUR SOLUTION

CAESAR II

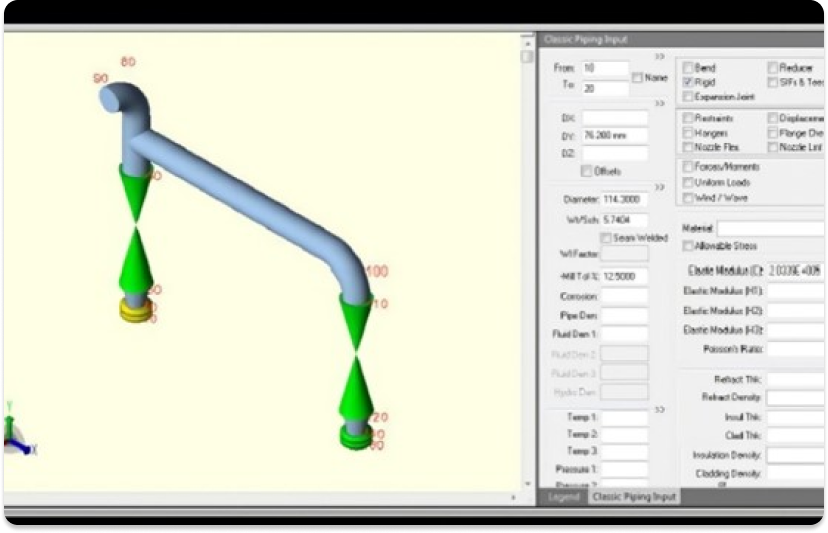

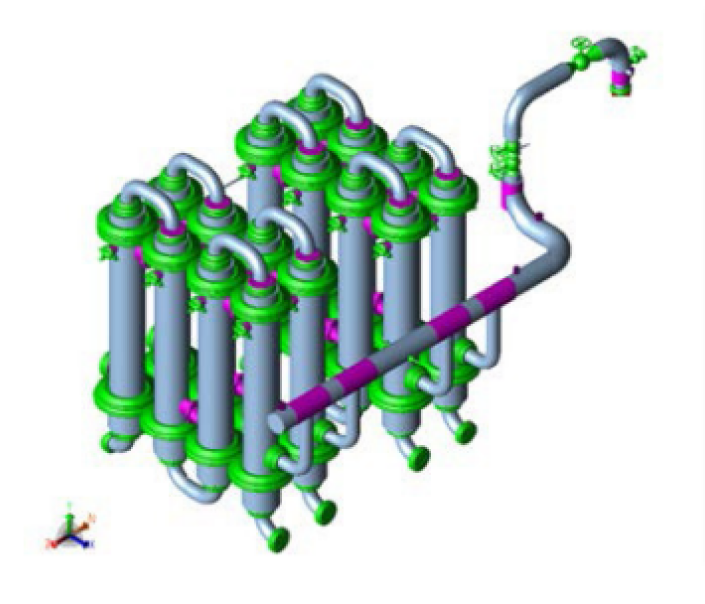

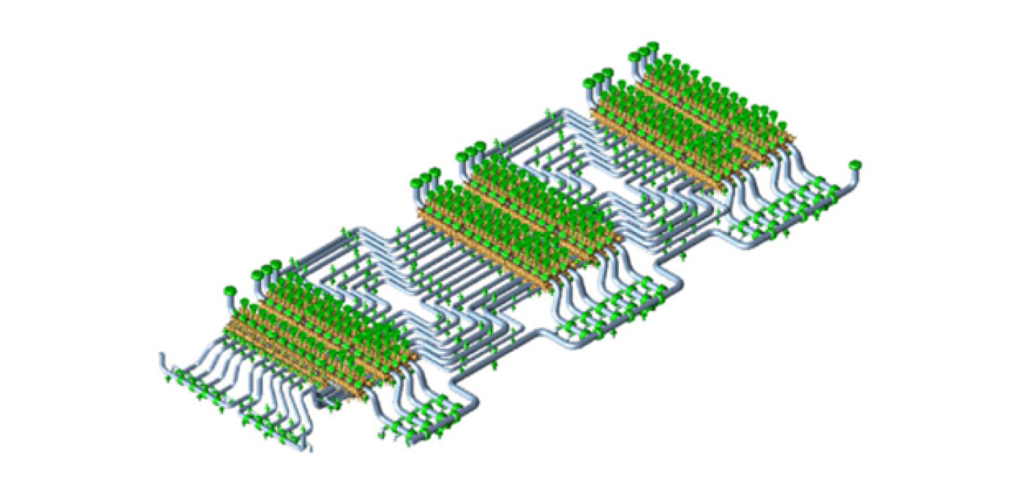

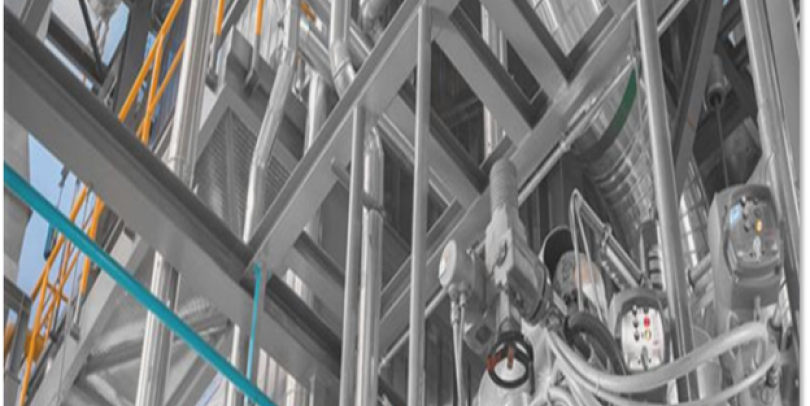

CAESAR II® is the industry standard for pipe stress analysis, letting you build, assess and report on piping systems of any size or complexity in accordance with more than 35 international piping code standards and many environmental and equipment guidelines. Integration with CAD design packages lets you quickly import models, reducing risk for errors and costly iteration time between CAD and Stress Analysis divisions.

LOOKING FOR CAESAR II?

LOOKING FOR CAESAR II?

Benefit

Reduce Manpower Error

Easy to input, display all the data and modify

Design under international code and standards

Save time for design and Analysis and be more accurate

Graphic in program can define for easy to evaluate

Animate for help to analysis model

Reduced Modeling Time

Reduced Modeling Time Save time modeling, so you can focus on your stress analysis. Experience superior usability with List Input grids and functionality that lets you work straight from the 3D model. Right-click menus and a functional toolbar layout with customization available lets you work quickly. Integration with CAD design packages lets you quickly import models, reducing risk for errors and costly iteration time between CAD and Stress Analysis divisions.

Robust Load Case Definitions/Manipulation

Robust Load Case Definitions/Manipulation Your customized load case definitions can be imported or exported through an easy to use template. Select to bypass or exclude certain cases from your analysis to speed up analysis time and focus on the conditions of interest. Use the Group Edit view to make quick changes to multiple load cases at once. Use the List view for creating new load cases, filtering and sorting on columns. Automatic renumbering of load cases upon deletion of cases, with easy review of the impacts on combination cases.

Advanced Graphics

Advanced Graphics Experience 3D model graphics with fast response times to model actions and intelligent refreshes. The graphics engine provides real-world representation for rigid components, supports and hangers, displacements, rotations, forces, and moments on the piping model.

Advanced Analysis and Reporting

Advanced Analysis and Reporting Access third-party tools for finite element analysis from the main menu, including free access to the recently published ASME B31J-2017 calculations for SIFs and K factors. Quickly send and translate through FEATools™, compare multiple file results, assess the sensitivity of model elements, and evaluate nozzle/branch connections with NozzlePRO™.

Advanced Analysis and Reporting

Advanced Analysis and Reporting In addition to the evaluation of a piping system’s response to thermal, deadweight, and pressure loads, CAESAR II analyzes the effects of wind, support settlement, seismic, and wave loads. Nonlinear effects such as support lift-off, gap closure, and friction are included. Select the proper springs for supporting systems with large vertical deflections. Analysis accounts for seismic second-degree flexibility and bends plasticization. Dynamic capabilities include modal, harmonic, response spectrum, and time history analysis. Quickly send analysis and time history results to output reports or the file format of your choice (MDB, Excel, Word, etc.)

Comprehensive Equipment Analysis

Comprehensive Equipment Analysis Associate multiple load conditions and multiple types of equipment in the Equipment Manager, which has connectivity to load cases used in your piping analysis. Experience a user-friendly interface and comprehensive reports. Analyze your critical flanges and flange assemblies against the EN-1591 code standard using a similar easy-touse manager, which automates much of the detailed flange input. Nuclear Industry Compliance CAESAR II complies with ASME NQA-1 quality assurance (QA). Subscribe to the CAESAR II QA and Reporting service to stay fully informed about issues and software changes. This notification service meets U.S. federal requirements 10 CFR Part 50 App. B. and 10 CFR Part 21.

Powerful Integration Capabilities

Powerful Integration Capabilities CAESAR II offers robust interfacing with CAD-based software, such as CADWorx Plant and Intergraph Smart® suites, using established industry formats (such as PCF and Isogen®). This lets you bring in data from other systems, carry it on to integrating solutions after analysis, and track support details. Import structural models from software such as CADWorx Structure or GT STRUDL®, and account for structural stiffness in the analysis. CAESAR II combined with GT STRUDL lets you share load details post-analysis so stress analysis and civil/structural groups work together without duplicating information and efforts.

CEASAR II

EcoSys Solutions

- Static Analysis

- Dynamic Analysis

- Intuitive Analysis Model Creation

- Design Tools and Wizards

- Load and View Plant Model

- Comprehensive Error Checking

- Robust load case definitions

- User-Definable Reports

- Wind and Wave Analysis

- Seismic and Support Settlement Analysis

- 38 International Piping Codes

- Extensive Material Databases

- Steel Databases and Modeling

- Expansion Joint Databases

- Hanger Design and Databases

- Integrates Intergraph Smart 3D® andCADWorx® Plant Design Suite

- Results Export to Microsoft® Excel®, Word, and MDB Files

BRICS CAD

Codes

Process: ASME B31.3, w/ Ch. IX, BS 806, JPI, HPGSL, EN 13480-1, CODETI

Power: ASME B31.1, B31.9, ASME B31.5, TBK 5-6, EN 13480-1, Stoomwezen, Swed. Method 1 & 2

Nuclear: ASME Section II, Class 2 and 3, RCC-M C and D

FRP: ISO 14692, UKOOA, BS-7159

Equipment/Components: EN-1591, WRC 107/537/297, API 560, 610, 661, 617, PD 5500, HEI, NEMA SM23, B31G, WRC 107/537/297, AISC

Offshore/Pipelines: ASME B31.4, w/ Ch. XI, and Ch IX, ASME B31.8, w/ Ch. VIII, CAN Z662, w/ Ch. 11, DNVGL-ST-F101, PD 8010, Part 1 and 2

Environmental: ASCE 7, NBC, IBC, UBC, EN 1991 GB 50009, Mexico NBR 6123, IS 875, BS 6399, As/Nzs 1170, KHK L1 and L2

SUCCESS CASES

Our Past Project

Our engineering success cases are a testament to our expertise and a demonstration of our ability to deliver exceptional results. Trust us to exceed your expectations and provide innovative solutions that drive your success.

Mumbai – INDIA

As- Built S3D Modelling From Scan Data & Dummy Model For Refinery Plant

Performed Piping & pipe supports modelling using dummy model and P&ID’s, Equipment foundation & Circular Platform modelling using dummy model and equipment GA drawings. Civil Underground modelling, Pipe rack, Technology Structure modelling using dummy model, To Do list & IFC clearing.

Chon buri – Thailand

Preparation Of Spool Drawing For Fabrication Company

Completed the preparation of spool drawings with customized style as per customer requirement, imported PCF files, checked out files, adding welds as per welding philosophy and generation of Spool. Drawings using customized style as per customers’ requirements.

Looking for a First-Class of Engineering Solutions?

CONTACT US

Headquarter

OFFICE

Locations

OUR NETWORKS

- Bangkok, Thailand

- Rayong, Thailand

- Mumbai. India

- SHARJAH, UAE

- Yangon, Myanmar

- Haeundae-Gu, Soth Korea

- United States