AX3000

OUR SOLUTION

AX3000

AX3000 is the result of years of collaboration between development team and engineers who have experience in the plant-engineering sector as well as technical schools and universities specializing in process engineering and energy management. The key benefit of AX3000 is a simple user interface, which can be learned with great end-user success. AX3000 is flexible and can be adopted easily. With continuous development you can be sure the investment in time will be worthwhile.

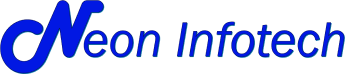

Lines, blocks, and material tables form the basis of systems created in AX3000. Three-dimensional systems can automatically be created from the inputs; variants can simply be created based on different parameters. “Equal Friction Loss” is commonly used as a calculation method, regarding maximum velocity. This calculation is based on the Darcy-Weisbach equation, considering the roughness of the material and tables for loss coefficients. Easyline Systems are divided into supply and exhaust air by the starting points. Duct design fundamentals include the flowrate of the outlets, components, fittings, and materials. Dimensioning can be accomplished by entering the cross section, volume flow or R-value. By defining the design conditions; the system is dimensioned, calculated and drawn in 3D. All data relevant for the system calculation is saved immediately and is recallable and changeable at any time.

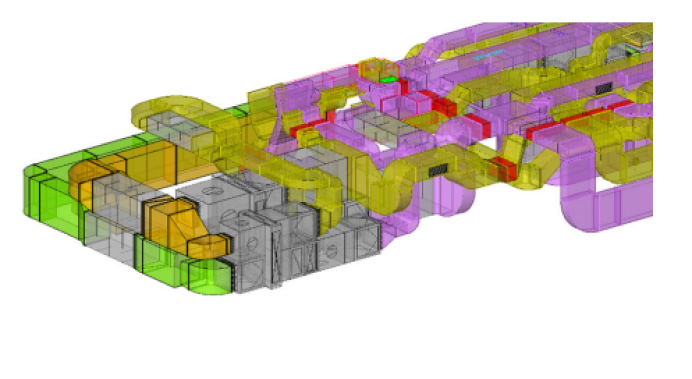

The heating system can easily be drawn using the Easyline system to define centerlines for supply and return piping. The start point defines the system parameters for material and system temperature. Fan coils, radiators or floor heating systems are typical load points. Equal friction loss for sizing utilizes calculations based on the Darcy-Weisbach equation, considering the roughness of the material and tables for loss coefficients. The result of the Easyline method is a fully planned 3D piping system, including pipes, fittings, components, valve settings and pressure loss calculations.

The AX3000 Sanitation module includes everything needed to design potable water, wastewater, and fire sprinkler piping systems. Every load point has connectors to connect the system. Typical load points are sinks, toilets, showers, washing machines, etc. The Easyline method helps size and route the system using hydraulic calculations based on Darcy-Weisbach and Prandtl-Colebrook equations. The result is a fully planned 3D piping system, including pipes, fittings, components, valve settings and pressure loss calculations.

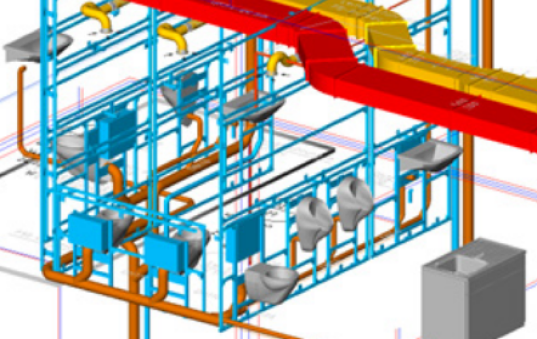

The AX3000 Electrical module allows easy placement of electrical elements (switches, receptacles, etc.) and their connection via conduits. There are also tools to provide efficient design of cable ladders and trays; based on manufacturer databases, including posts and hangers.

SUCCESS CASES

Our Past Project

Our engineering success cases are a testament to our expertise and a demonstration of our ability to deliver exceptional results. Trust us to exceed your expectations and provide innovative solutions that drive your success.

Mumbai – INDIA

As- Built S3D Modelling From Scan Data & Dummy Model For Refinery Plant

Performed Piping & pipe supports modelling using dummy model and P&ID’s, Equipment foundation & Circular Platform modelling using dummy model and equipment GA drawings. Civil Underground modelling, Pipe rack, Technology Structure modelling using dummy model, To Do list & IFC clearing.

Chon buri – Thailand

Preparation Of Spool Drawing For Fabrication Company

Completed the preparation of spool drawings with customized style as per customer requirement, imported PCF files, checked out files, adding welds as per welding philosophy and generation of Spool. Drawings using customized style as per customers’ requirements.

Looking for a First-Class of Engineering Solutions?

CONTACT US

Headquarter

OFFICE

Locations

OUR NETWORKS

- Bangkok, Thailand

- Rayong, Thailand

- Mumbai. India

- SHARJAH, UAE

- Yangon, Myanmar

- Haeundae-Gu, Soth Korea

- United States