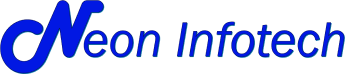

Thercast

OUR SOLUTION

Thercast

Simulation software for casting processes

THERCAST® is a 3D finite-element software designed for simulating foundry, continuous casting, and ingot casting processes. With THERCAST®, you can efficiently and precisely analyse your entire manufacturing process, from the initial casting stage to complete solidification. This enables you to predict and prevent manufacturing defects, ensuring the production of high-quality components while minimizing the prototyping phase.

Industry Applications

Industry Applications

Automotive Industry | Construction Sector | Steel Industry

THERCAST®: Your Partner at Every Stage of Production

- R&D Phase

- Quotation Phase

- Accelerated Time-to-Market

- Quality Assurance

- Engineering Support

- Knowledge Retention

Key Advantages to Outperform Your Competition

- Slice-Based Calculations

- Comprehensive Thermo-Mechanical Analysis

- Control of Liquid Fraction Zone

- Anticipation of Solidified Thickness

- Deformation Rate Analysis

- Coupled Fluid and Solid Mechanics

Looking for a First-Class of Engineering Solutions?

SUCCESS CASES

Our Past Project

Our engineering success cases are a testament to our expertise and a demonstration of our ability to deliver exceptional results. Trust us to exceed your expectations and provide innovative solutions that drive your success.

Mumbai – INDIA

As- Built S3D Modelling From Scan Data & Dummy Model For Refinery Plant

Performed Piping & pipe supports modelling using dummy model and P&ID’s, Equipment foundation & Circular Platform modelling using dummy model and equipment GA drawings. Civil Underground modelling, Pipe rack, Technology Structure modelling using dummy model, To Do list & IFC clearing.

Chon buri – Thailand

Preparation Of Spool Drawing For Fabrication Company

Completed the preparation of spool drawings with customized style as per customer requirement, imported PCF files, checked out files, adding welds as per welding philosophy and generation of Spool. Drawings using customized style as per customers’ requirements.

Looking for a First-Class of Engineering Solutions?

CONTACT US

Headquarter

OFFICE

Locations

OUR NETWORKS

- Bangkok, Thailand

- Rayong, Thailand

- Mumbai. India

- SHARJAH, UAE

- Yangon, Myanmar

- Haeundae-Gu, Soth Korea

- United States