WQMS

OUR SOLUTION

WQMS

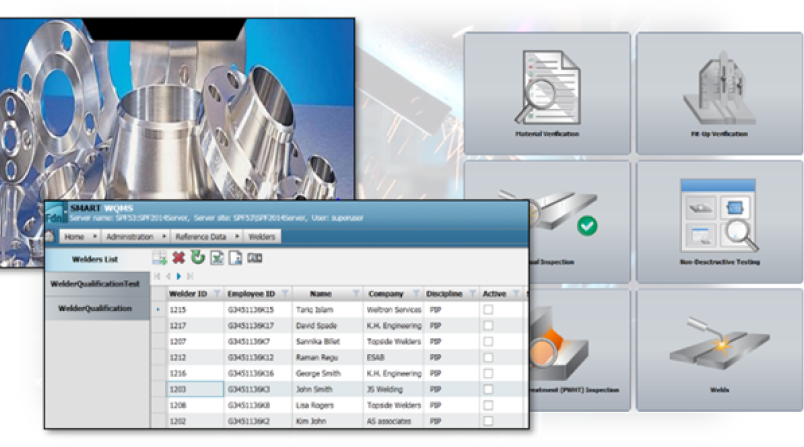

Intergraph Smart® Weld Quality Management System (WQMS) is a comprehensive application that integrates with engineering, fabrication and construction processes for welding quality control and material traceability. It includes quality monitoring of welds and non-destructive testing (NDT) inspections for both piping and structural fabrication activities, including standard reporting capabilities, documentation and automated handover (final documentation) through the inherent EDMS features.

LOOKING FOR WQMS ?

WE ARE HERE TO HELP

Increase ROI

Smart WQMS makes it possible to accelerate the execution of EPC Projects at lower cost without compromising quality or accuracy.

Improve Visibility

Smart WQMS enable full traceability from design to acceptance, helping the fabricator to monitor, measure and control critical processes.

Improve Efficiency

The user-friendly interface with dashboard based icons and a spreadsheet looks and feel is easy to use. You have a option of editing tables directly or loading data from an external sources.

Industry Requirements

Add required QC Related items are addressed, including welds, repairs and re-welds details, as well as fit-up visuals, NOT and Posts Weld Heat Treatment (PWHT) records.

Integrated Quality Control & Tracking

This single common platforms enables you to streamline fabrication workflows, eliminated manual entry and platform change management more efficiently.

Welder Database Management

Smart WQMS includes welder maintanance records to keep qualifications up-to date and maintain full welder histories.

BENEFIT

Industry Requirements and Practices

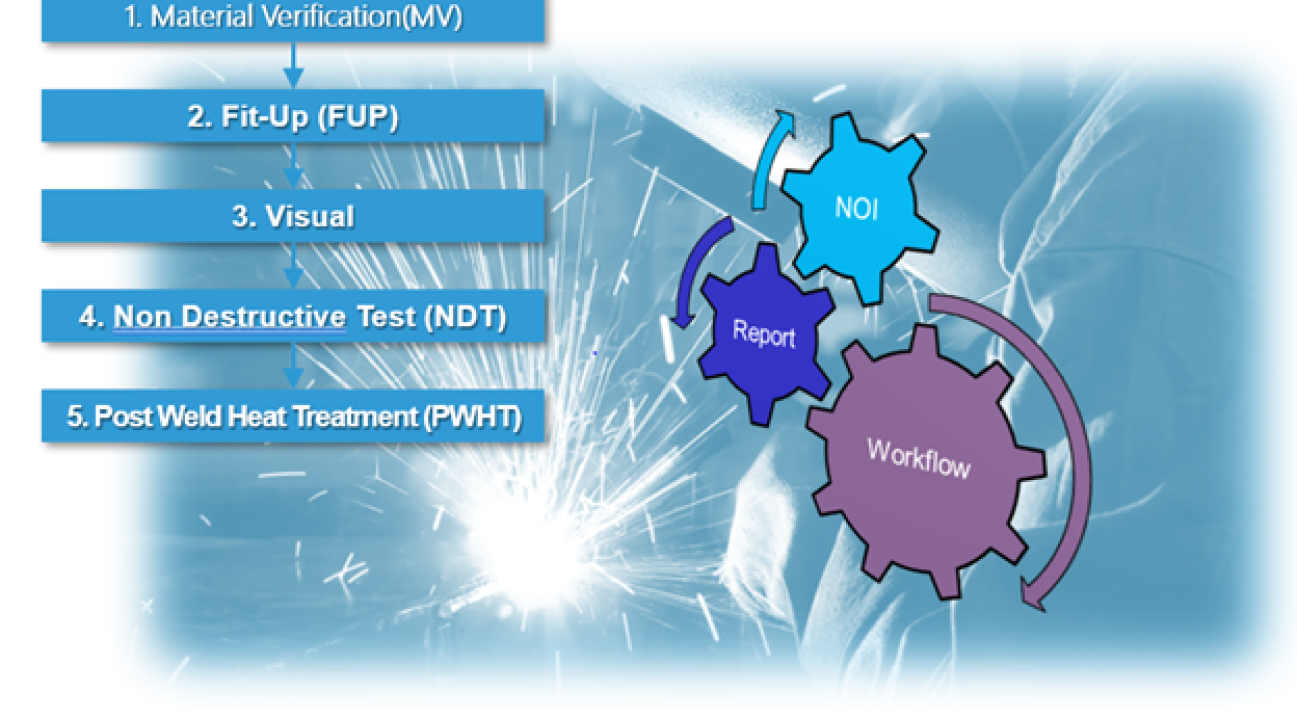

To claim completion for a fabrication or construction task, quality acceptance is a mandatory step according to industry practices. Quality Control (QC) functions are a fundamental part of Smart WQMS. All required QC-related items are addressed, including welds, repairs, and re-weld details, as well as fit-up, visual, NDT, and Post Weld Heat Treatment (PWHT) records. All of the data will be composed and incorporated so that the owner or main contractor can have precise data at all stages of the project.

As part of Intergraph’s integrated approach to engineering, procurement, fabrication, and construction, Smart WQMS works with piping and structural data from Intergraph Smart 3D or other CAD systems, covering all operational components in the fabrication process. It supports both minor projects as well as the complex, mega-sized project requirements. In addition, the solution complies with industry requirements.

BENEFIT

Intergrated Quality Control And Tracking

- Intergrated Quality Control And Tracking

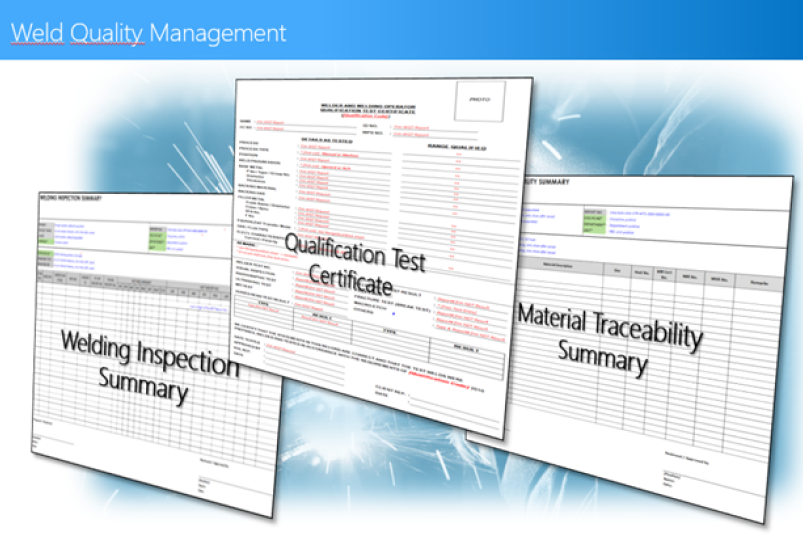

- Smart WQMS enables the automated production of quality documentation for the testing and certification of structural parts and pipe spool fabrication and erection at the onstruction site. By integrating the production of documentation with corresponding engineering drawings and data, you can take advantage of a single common platform to:Streamline fabrication workflows

- Eliminate manual entry

- Perform change management more efficiently

- The pre-defined inspection sequences and workflow-driven functionality offered by Smart WQMS ensure that all steps of quality checks and verifications are recorded. Comprehensive weld-map data provides complete traceability for welds. This data can be created automatically

from the integration of engineering systems, without the need for manual input.

Smart WQMS covers the entire cycle of inspection activities, including Notice of Inspection (NOI). Full status and progress information and material traceability are maintained for both piping and structural materials by detailing the location and status within the fabrication process. This enables the system to record and present the progress of welding and NDT inspection at any point in time. It also ensures that full material reconciliation can be performed as soon as the project is completed. This information is important for the overview of acceptance of onsite work and further supports the claiming and invoicing process.

Looking for a First-Class of Engineering Solutions?

SUCCESS CASES

Our Past Project

Our engineering success cases are a testament to our expertise and a demonstration of our ability to deliver exceptional results. Trust us to exceed your expectations and provide innovative solutions that drive your success.

Mumbai – INDIA

As- Built S3D Modelling From Scan Data & Dummy Model For Refinery Plant

Performed Piping & pipe supports modelling using dummy model and P&ID’s, Equipment foundation & Circular Platform modelling using dummy model and equipment GA drawings. Civil Underground modelling, Pipe rack, Technology Structure modelling using dummy model, To Do list & IFC clearing.

Chon buri – Thailand

Preparation Of Spool Drawing For Fabrication Company

Completed the preparation of spool drawings with customized style as per customer requirement, imported PCF files, checked out files, adding welds as per welding philosophy and generation of Spool. Drawings using customized style as per customers’ requirements.

Looking for a First-Class of Engineering Solutions?

CONTACT US

Headquarter

OFFICE

Locations

OUR NETWORKS

- Bangkok, Thailand

- Rayong, Thailand

- Mumbai. India

- SHARJAH, UAE

- Yangon, Myanmar

- Haeundae-Gu, Soth Korea

- United States